The laboratory of SGS Germany GmbH in Munich on Hofmannstrasse is currently moving to the new location in Puchheim, on Benzstrasse in the west of Munich. Specifically, this affects the accredited testing areas of electromagnetic compatibility (EMC), radio, product safety, fire and flammability testing, and lighting technology. At the same time, the Munich Functional Safety and Homologation divisions of SGS-TÜV Saar GmbH will also be relocated.

SGS, headquartered in Geneva, is the world’s leading inspection, testing, verification, and certification company, with 2,650 locations and 98,000 employees.

At the new location at Benzstrasse 26 + 28, in Puchheim, two buildings with approx. 6,300 m2 of laboratory and office space have been rented from the company, Hallenwerk. This means that we now have significantly more testing facilities and test capacities at our disposal.

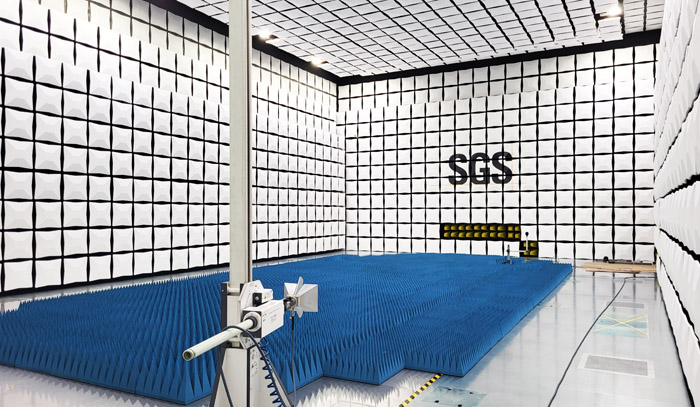

A section of the existing building was removed by the landlord and rebuilt to a precise fit over an area of around 1,800 m2 and at the appropriate building height without columns, in order to accommodate the measuring chambers for the new EMC laboratory. Albatross Projects began constructing the new measuring chambers already in May of this year. In addition to a new 10 m absorber chamber and two new 5 m absorber chambers, two additional absorber chambers and three shielded measuring rooms will be relocated from the previous laboratory site and set up in the new test hall.

The new 10 m EMC chamber, in particular, has significantly expanded technical capabilities compared to the previous chamber: a turntable with a diameter of 6 m and a load capacity of 10 tons (dynamic) or 35 tons (static) as well as a heavy-duty area outside the turntable for vehicles and heavy test specimens up to 15 tons/m2, 20 tons axle load, or 35 tons total weight. All this in conjunction with an entrance gate measuring 4.2 x 4.2 m.

In comparison to conventional 3 m chambers, the two 5 m absorber chambers are also designed to meet the future requirements and measuring distances for medium-sized test specimens. In this respect, the new EMC laboratory offers excellent and norm-compliant testing options – from small components to large and heavy test samples or vehicles. In terms of power supply, the EMC laboratory is designed for test specimens up to 125 A/400 V and 1,000 VDC or 500 ADC for electromobility.

The new location offers significantly better logistics and delivery options, especially for large and heavy test samples and vehicles.

The product safety department will also have more testing space and capacity.

In conjunction with the move, our lighting technology laboratory will have an additional 18 m-long dark room, providing more options for measuring the photometric properties and photobiological safety of lamps, luminaires, and lasers, among other things.

This means that the relevant areas will also be perfectly positioned for testing and certification in the future – from small components to complex and large systems from the areas of lamps and luminaires, IT, audio/video, laboratory, in-vitro and medical devices, as well as rail, industry, and automotive, including electromobility, plus combined equipment in conjunction with radio systems.